Online Heating Gallery

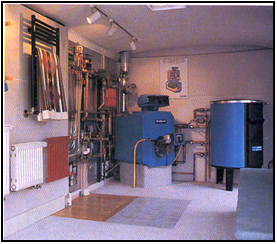

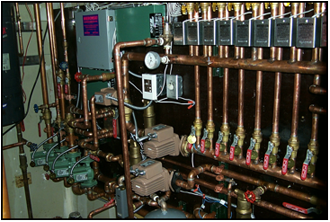

The following page shows before and after pictures of Breckenridge heating systems repaired by Wieronski Plumbing & Heating Inc. We are providing these pictures to show that there is a difference in the quality of installations from one company to another.

Some of these show that the original installations were not allowing the homes to heat properly.

Some were operating inefficiently resulting in high utility costs.

Several systems failed within a short time and required complete replacement.

Some systems were actually installed dangerously.

All of the above problems could be traced back to poor installation, improper design, and the use of inferior material.

Wieronski Plumbing & Heating Inc. takes pride in the workmanship of heating systems. Being in the service business for over 27 years, we have learned which equipment is long-lasting and which equipment fails prematurely. When designing quality heating systems, we only use the best material, equipment and components that have demonstrated to be long lasting, and that will provide you with a heating system that will give many years of dependable service.

Wieronski Plumbing & Heating Inc. is locally known for quality service, and we also have an excellent reputation with the boiler manufacture reps located in Denver.The following is a quote from Dennis Bellanti, a boiler representative who has inspected numerous heating systems.

"I have seen many Buderus (boiler) installations including some in Germany. I truly believe your installations are some of the finest craftsmanship I have seen anywhere"

In 2008 Wieronski Plumbing and Heating Inc. was called out to inspect a new 4 unit complex where two of the units had Carbon Monoxide detectors sounding an alarm.

Upon inspection of the project Wieronski Plumbing and Heating Inc. was informed a local Mechanical Company had finished the heating system installations six months earlier. During that time the Mechanical Contractor kept telling the home owners and contractor that everything was okay and installed up to code. However, they could not explain why the Carbon Monoxide alarms kept sounding an alarm.

Wieronski Plumbing and Heating Inc. inspected the four unit complex and many safety problems and code violations were discovered. A nine page inspection report was provided to the homeowners and contractor. The contractor was then able to go back to the original mechanical contractor and have the problems corrected. This resulted in financial savings to the contractor, but more importantly in all probability it prevented someone from being scalded, injured from Carbon Monoxide or hurt due to the improper installation of the heating system.

The problems discovered by Wieronski Plumbing and Heating Inc. in one of the four units were as follows:

Boiler chimney was not high enough above the roof as required by code. When a vent/chimney is not high enough, heating equipment will not vent properly. This improper venting can allow flue gases which may contain Carbon Monoxide to enter the home.

Water heater did not have any controls installed to control the temperature of the hot water. This improper installation was allowing the water heater to over heat to 180 degree.

With domestic hot water temperatures of 150 degrees 3rd degree burns can happen in less than 1 second for a child and less than 2 seconds for an adult. This was a serious health risk that needed to be corrected as soon as possible.

1" water service was reduced down to ½". This improper reduction in water piping size was restricting water flow to the home.

Water heater did not have a temperature and pressure relief valve installed as required by code.

A valve was improperly installed between the safety relief valve and the boiler. This improper installation was against code and could have caused a dangerous over pressurization of the boiler which could have resulted in damage to the home.

Ball valve that was installed to isolate the boiler was installed in the wrong location.

This improper installation would have caused the water to be turned off to the entire home when the water was turned off to the boiler.

Heating system did not have proper two temperature control system.

Air scoop was installed improperly.

Two heating circulators were installed improperly.

Thermal expansion tank installed was not installed as required by code.

Wieronski Plumbing & Heating Inc. designed and installed a miniature heating system in the trailer shown below which is used for training throughout the state of Colorado. This trailer is also used at home shows to help explain to customers how radiant heat works. The miniature heating system in this trailer was featured in the September 1996 issue of Plumbing & Mechanical magazine.

Our supplier has thanked us many times for the design and installation we made for the trailer. They say that at every training class someone mentions how well designed and installed the trailer heating system is.

|

|

|

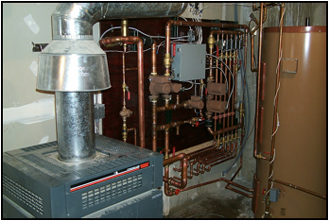

BEFORE: |

AFTER: |

|

|

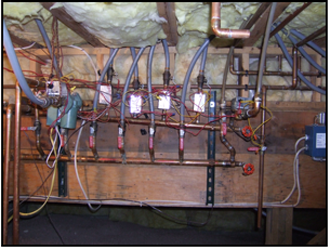

BEFORE: |

AFTER: |

|

|

BEFORE: |

AFTER: |

|

|

BEFORE: |

AFTER: |

|

|

BEFORE: |

AFTER: |

|

|

BEFORE: |

AFTER: |

|

|

BEFORE: |

AFTER: |

|

|

|

|

BEFORE:

BEFORE: |

AFTER: |

| All of the above listed problems were corrected by installing a properly designed control panel and new boilers. | |